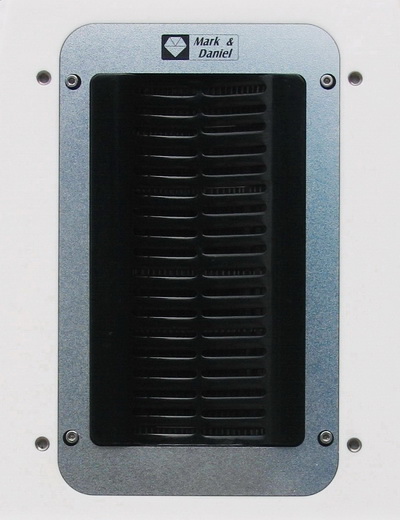

DM-3, Wideband AMT Dreams Driver

Model DM-3a Dreams is the enlarged version to the DM-1 AMT wideband driver that specially designed to match with the Apollo floor-standing sound systems, responsible from 500Hz up to 20 KHz.

Most commonly used by hi-fi industry today for making the ribbon tweeters (also used by M&D’s pleated Dreams drivers), the etched aluminum circuitry is laid on a very thin 0.025mm (1 mil) polyimide (also known as Kapton) film as the substrate to constitute the voice diaphragm; due to the outstanding characteristics of polyimide such as extremely light weight, high temperature-resistance (180-250º C), excellent durability, and so forth.

However, from M&D’s own study, we found that the attached mass and hardness of the present polyimide substrate could still amount to certain obstruction for perfect diaphragm movements during sound reproduction. In order to further cut down the substrate moving mass and enhance the pleated diaphragm compliance, after long research, M&D has developed the unique technique and craft to further reduce the substrate to only one-half of its original thickness. This successful development allows us to apply the rare, super-thin 0.0125mm (0.5 mil) polyimide material in re-formulating our new Dreams series voice diaphragms.

Not only this 0.5 mil super-thin polyimide itself incurs much expensive production cost, the higher level of skilled craftsmanship throughout the entire manufacturing process of the Dreams diaphragm are painstakingly time consuming. However, this innovative breakthrough has been proven worthwhile; the new DM-3 Dreams AMT wideband driver exhibits significant improvement over the original version on operating bandwidth, transient response, and sound quality characteristics.

Compare the DM-3 to any other speaker --- its large composite diaphragm provides 150 times more driving surface than a 1” dome tweeter! This super large structure guarantees stunning output capability, and very high power handling, with the lowest FMD pollution throughout the entire operating bandwidth.

This super large diaphragm is sunk into an extremely strong magnetic loop, curved shape, and built by as many as to 51 units of NdFeB magnets! A truly sophisticated and expensive structure to ensure proper operation of the driver yields a satisfactory ±30° horizontal dispersion (-5dB) within a 500Hz to 7KHz wideband. Vertically, it has a low dispersion characteristic effectively avoiding un-necessary reflections by ceiling or floor for a better clearness while listening.

Typical DC impedance of the DM-3 is 3.5 (±0.2) Ohms, completely resistive to whole audio band, without any resonance, without inductive or capacitive contributes. This perfect impedance characteristic provides a highly stable operation to power amplifier; it also allows for very easy crossover network design.

DM-3 has the efficiency to 88 dB/2.83V/1m in average. The module is sized (H) 254mm x (W) 150mm x (D) 44mm, and the iron frame of 4mm thickness is extremely rigid and heavy in construction with each module weighing up to 3.2 Kg (7.2 lb).

Different from an assembly line produced product, the manufacturing process of the Dreams module is both time and labor intensive, requiring extensive hours and hours to assemble and test. Rather than just a simple, mass-produced, assembly line manufactured tweeter, the Dreams driver requires utmost dedication in both precision technology and artistic craftsmanship throughout its creation.

|